Importance of BMS in the Lithium Battery

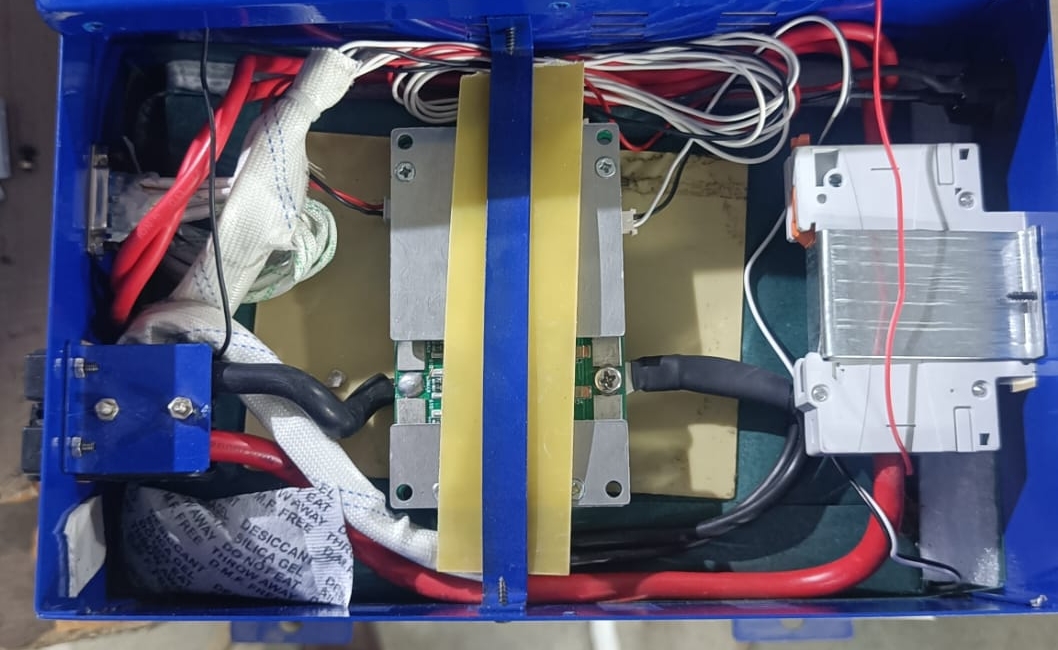

A Battery Management System (BMS) is critical for Lithium-ion batteries because it acts like an electronic brain, ensuring their safe, reliable, and long-lasting operation. Here’s why a BMS is so important:

https://suvastika.com/exploring-the-importance-of-battery-management-system-bms/

https://lithiuminverter.in/battery/the-benefits-of-replacing-gensets-with-lithium-based-battery-ess/

Safety:

- Lithium-ion batteries are susceptible to damage from overcharging, over-discharging, overheating, and short circuits. A BMS constantly monitors these parameters and can take corrective actions like shutting down the battery to prevent fire or explosions.

Lithium-ion batteries are handy, but it’s important to handle them safely because:

Fire and Explosion Risk: Damaged, improperly used, or incorrectly charged lithium batteries can overheat, catch fire, or even explode. This can cause serious injuries and property damage.

Lithium-ion batteries are incredibly common, powering everything from our laptops and smartphones to electric vehicles and even spacecraft. They are lightweight, rechargeable, and hold a lot of power for their size. However, they do come with a potential safety risk: fire and explosion.

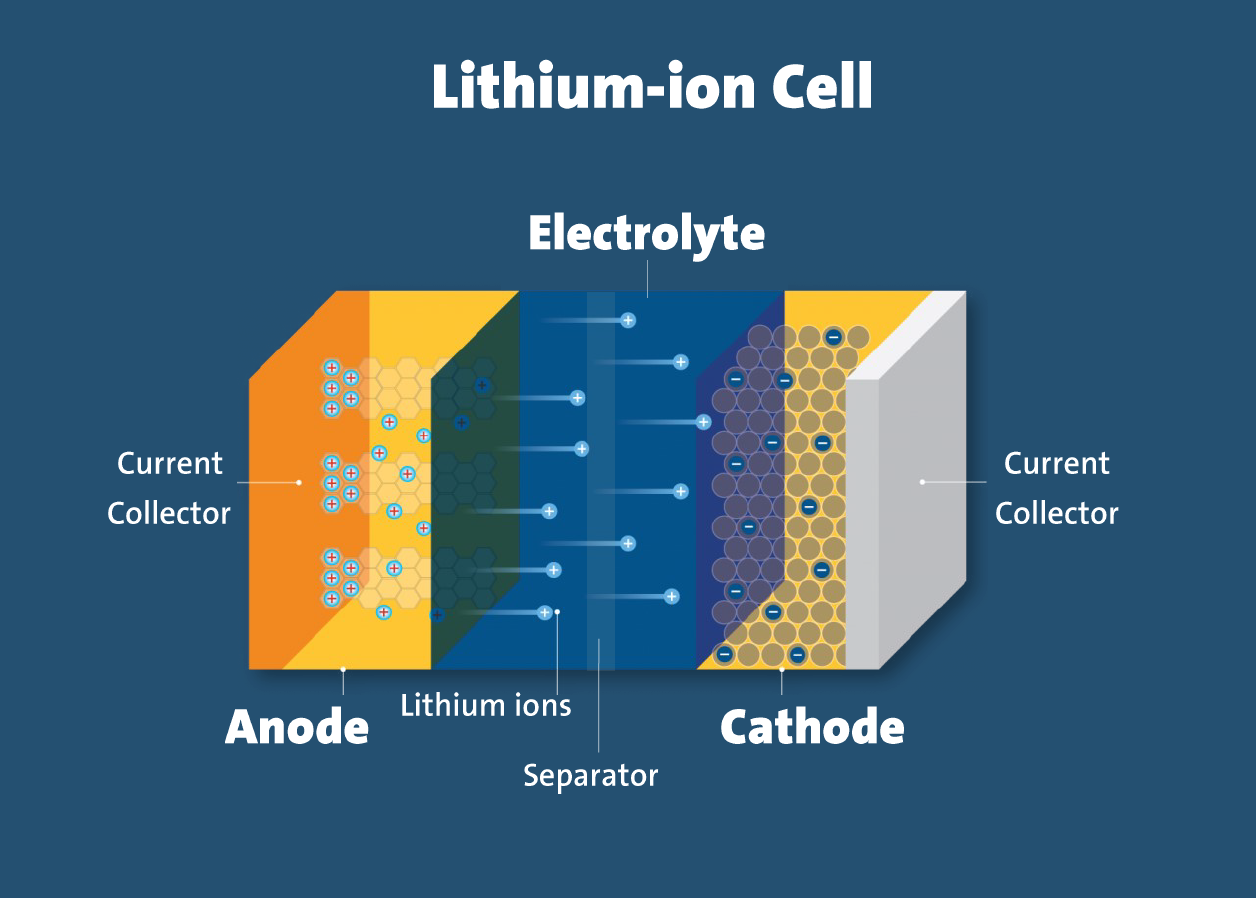

Lithium batteries contain flammable electrolytes and can overheat under certain conditions, which can lead to a process called thermal runaway. In thermal runaway, a battery failure creates heat, which can cause the battery to vent flammable materials and combust. This can quickly escalate into a fire and even an explosion, especially if multiple batteries are involved.

Here are some of the factors that can increase the risk of fire or explosion in a lithium-ion battery:

- Physical damage: Punctures, crushing, or bending of a battery can damage its internal components and increase the risk of fire.

- Extreme temperatures: Exposing a lithium-ion battery to very high or low temperatures can damage it and increase the risk of fire.

- Manufacturing defects: Faulty batteries can malfunction and overheat.

- Improper use: Using a battery that is not designed for a particular device or using an incompatible charger can damage the battery and increase the risk of fire.

Public Safety Concerns: Lithium batteries are in many everyday devices so widespread safety issues can impact a large number of people.

Lithium-ion batteries are incredibly useful, powering everything from our phones to electric vehicles. However improper use or malfunctions can lead to safety hazards. Here’s why public safety concerns are important with lithium batteries:

-

Fire Risk: Lithium batteries can overheat and ignite, causing fires. This is especially dangerous in enclosed spaces like homes or airplanes.

-

Toxic Fumes: Battery fires release toxic fumes that can be harmful if inhaled.

-

Explosions: In extreme cases, a battery fire can lead to an explosion, causing serious injuries or property damage.

Public awareness and safety regulations are crucial to minimize these risks. Here are some ways to ensure safety:

- Using certified batteries: Look for batteries with safety certifications that indicate they meet specific safety standards.

- Proper handling and storage: Avoid physically damaging batteries, and store them in cool, dry places away from flammable materials.

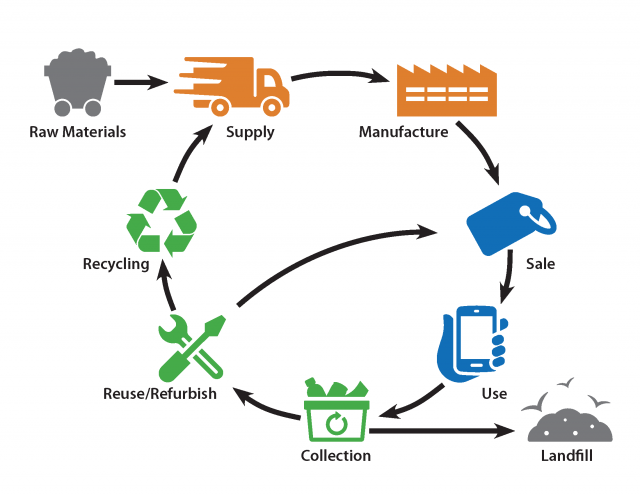

- Following disposal guidelines: Don’t throw away lithium batteries in regular trash. Look for designated recycling centers.

Environmental Impact: Lithium battery fires can release toxic chemicals and pollute the environment. Proper disposal is also crucial to avoid environmental hazards.

Lithium-ion batteries are a key component of the clean energy revolution, but their environmental impact is a crucial factor to consider. Here’s a breakdown of why:

Benefits:

- Enables renewables: Lithium-ion batteries store energy from renewable sources like solar and wind, making them more viable for widespread use.

Drawbacks:

- Mining: Lithium extraction can use significant water resources and harm local ecosystems, especially in sensitive areas like the Atacama desert.

- Recycling: Improper disposal of lithium-ion batteries is a major concern. They contain toxic materials that can leach into the environment if they end up in landfills. Current recycling methods are not always efficient or affordable.

Overall, the environmental impact of lithium-ion batteries is complex. While they are essential for enabling clean energy, their production and disposal need to be addressed for a truly sustainable future.

Here are some areas where improvement is happening:

- Sustainable mining practices: Research is underway to develop less water-intensive methods for lithium extraction.

- Improved recycling: Technologies are being developed to make lithium-ion battery recycling more efficient and cost-effective.

Battery Defects: Manufacturing flaws or cutting corners to reduce costs can increase the risk of battery failure.

attery defects are a big deal for lithium-ion batteries, and can impact them in a few key ways:

- Safety: Defects can increase the risk of fire or explosion. For instance, imperfections in the separator, which keeps the anode and cathode apart, can lead to internal short circuits [3].

- Performance: Battery life, capacity, and power output can all be reduced by defects. This is because defects can hinder the movement of lithium ions within the battery, reducing its efficiency [1].

- Lifespan: Defects can cause a battery to degrade faster over time. This means it won’t hold a charge for as long and will need to be replaced sooner

-

Importance of Battery Management Systems: These systems regulate battery function and prevent them from operating outside safe parameters.

Performance:

- A BMS balances the individual cells within a battery pack. This is important because no two cells are identical, and imbalances can lead to reduced capacity and lifespan.

- The BMS tracks the battery’s State of Charge (SOC) and State of Health (SOH), giving you valuable information about how much power is available and how well the battery is aging.

Longevity:

- By preventing damage and optimizing performance, a BMS significantly extends the lifespan of a Lithium-ion battery. This translates to cost savings and reduces environmental impact.

Overall, a BMS plays a vital role in making Lithium-ion batteries safe, reliable, and long-lasting for applications in electric vehicles, consumer electronics, and renewable energy storage.

Lifespan Definition Battery lifespan refers to the total duration a battery can deliver its intended performance before needing replacement. It’s typically measured in years or the number of charge-discharge cycles the battery can withstand before falling below a specific capacity threshold (often 80% of its original capacity).Lithium vs. Lead Acid Battery Lifespan

Lifespan Definition Battery lifespan refers to the total duration a battery can deliver its intended performance before needing replacement. It’s typically measured in years or the number of charge-discharge cycles the battery can withstand before falling below a specific capacity threshold (often 80% of its original capacity).Lithium vs. Lead Acid Battery Lifespan The Lifespan of Lithium vs. Lead Acid: A Comparative Study

The Lifespan of Lithium vs. Lead Acid: A Comparative Study