How to check if BMS is working?

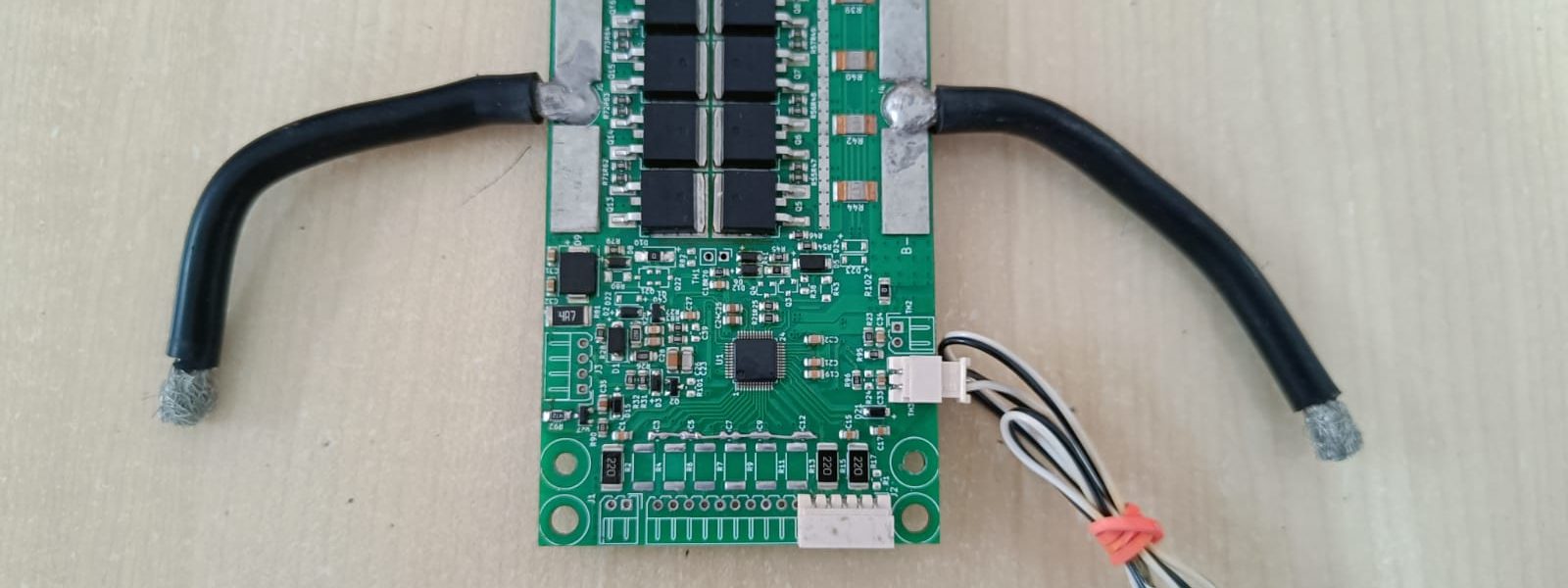

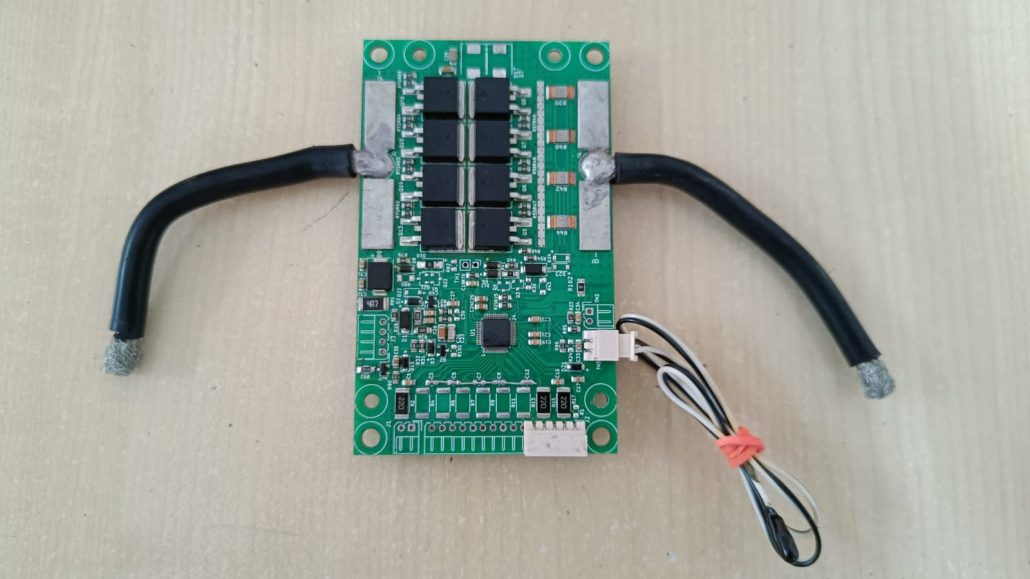

A BMS PCB, or Battery Management System Printed Circuit Board, is the heart of a BMS. It’s an electronic board with various components that work together to monitor and control a battery pack. Here’s a breakdown of how it functions:

How to check if BMS is working?

Monitoring:

BMS PCBA monitoring refers to the specific process of tracking and analyzing data collected by the BMS printed circuit board (PCBA). This data is crucial for ensuring the safe and efficient operation of the battery pack.

Here’s a closer look at what BMS PCBA monitoring typically involves:

Data Acquisition:

- The BMS PCBA continuously collects data from various sensors, including:

- Cell voltages – monitors the voltage of each cell in the battery pack.

- Current – tracks the current flowing into (charging) or out of (discharging) the battery.

- Temperature – measures the temperature of the battery pack.

Data Analysis:

- This collected data is then fed into the microcontroller on the PCBA.

- The microcontroller analyzes the data against pre-defined thresholds for safe operation.

- It checks for:

- Overvoltage or undervoltage of individual cells or the entire pack.

- Excessive charging or discharging currents.

- Temperatures exceeding safe limits.

How to check if BMS is working?

Alerts and Actions:

- If any parameter falls outside the safe zone, the BMS PCBA can trigger alarms or take corrective actions:

- Alerts might be visual indicators on the device itself or transmitted to external systems for monitoring.

- Corrective actions can involve:

- Disconnect the battery from the charger or load to prevent damage.

- Initiating cell balancing to equalize voltages between cells and improve battery health.

Additional Monitoring Features:

- Depending on the BMS PCBA complexity, monitoring can extend beyond basic parameters:

- State of Charge (SOC): This estimates the remaining capacity in the battery.

- State of Health (SOH): This indicates the overall health and degradation of the battery over time.

- Data logging: The BMS PCBA might store historical data on battery performance for further analysis.

By effectively monitoring the BMS PCBA data, you can gain valuable insights into the battery’s health and performance. This allows for:

- Early detection of potential issues: Identifying problems before they cause damage can prevent costly repairs or downtime.

- Predictive maintenance: Monitoring data can help predict when maintenance is needed, optimizing battery life and performance.

- Improved safety: By ensuring the battery operates within safe limits, BMS PCBA monitoring minimizes safety risks associated with battery failures.

How to check if BMS is working?

Overall, BMS PCBA monitoring plays a vital role in ensuring the safe, reliable, and efficient operation of battery packs across various applications.

-

The BMS PCB continuously monitors important battery parameters like:

- Voltage of individual cells and the entire pack

- Current flowing in and out of the battery

- Temperature of the battery pack

-

Sensors on the PCB collect this data and send it to the brain of the system:

Control and Protection:

BMS PCB control and protection are the two key functions that work together to safeguard your battery pack and optimize its performance. Here’s a detailed explanation of each:

Control:

-

Cell Balancing: Lithium-ion battery packs consist of multiple cells connected in series. Ideally, all cells should discharge and charge at the same rate. However, slight manufacturing variances or uneven usage can lead to imbalances. The BMS PCB can employ cell balancing to address this. It monitors individual cell voltages and, if a discrepancy arises:

- It activates passive balancing circuits that redistribute charge from higher voltage cells to lower voltage ones, bringing them closer to a balanced state.

- In some advanced systems, active balancing might be used, involving dedicated circuits to transfer charge more efficiently.

-

Current Management: The BMS PCB plays a crucial role in managing the current flow within the battery pack:

- Over-current Protection: If the charging or discharging current exceeds a safe limit, the BMS PCB can intervene by:

- Limiting the current electronically using MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors).

- Disconnecting the battery from the charger or load entirely in severe cases.

- Short-Circuit Protection: In case of a short circuit within the battery pack, the BMS PCB can quickly disconnect the battery to prevent damage from excessive currents and overheating.

- Over-current Protection: If the charging or discharging current exceeds a safe limit, the BMS PCB can intervene by:

How to check if BMS is working?

Protection:

The BMS PCB implements various safeguards to shield the battery from harmful conditions:

-

Overcharge Protection: Lithium-ion batteries can be permanently damaged by excessive voltage during charging. The BMS PCB monitors the total pack voltage and individual cell voltages. If the voltage reaches a pre-set overcharge threshold:

- It can terminate the charging process by disconnecting the battery from the charger.

- In some cases, it might activate safety features within the charger itself.

-

Over-discharge Protection: Deep discharging a lithium-ion battery below its minimum safe voltage can significantly reduce its lifespan or even cause permanent damage. The BMS PCB monitors the total pack voltage and individual cell voltages. If the voltage falls below a pre-set over-discharge threshold:

- It can disconnect the load to prevent further discharge.

- It might issue a warning or shut down the device entirely.

-

Temperature Protection: Extreme temperatures can degrade battery performance and safety. The BMS PCB monitors the battery pack’s temperature. If the temperature exceeds a safe limit:

- It might reduce the charging or discharging current to prevent further heating.

- In severe cases, it can completely disconnect the battery to allow it to cool down.

By implementing these control and protection features, the BMS PCB ensures the battery operates within safe voltage, current, and temperature ranges. This safeguards the battery from damage, extends its lifespan, and maximizes its performance

- A microcontroller on the PCB analyzes the data based on pre-programmed safety thresholds.

- If any parameter exceeds the safe limits (e.g., the voltage gets too high or low, the temperature rises excessively), the microcontroller takes corrective actions:

- It can disconnect the battery from the charger or load (depending on charging/discharging) using electronic switches (MOSFETs).

- In some cases, it might initiate cell balancing to equalize voltages between cells in the pack.

Overall, the BMS PCB works to:

- Ensure safe operation of the battery by preventing overcharging, over-discharging, and overheating.

- Maximize battery lifespan by keeping it within optimal operating conditions.

- Improve battery performance by managing current flow and cell balancing.

How to check if BMS is working?

The complexity of a BMS PCB can vary depending on the application. Some basic PCBs might just focus on essential protection features, while more advanced ones can offer additional functionalities like data logging and communication with external systems.